Model of the river paddle steamer "Bohemia". Sudomodellism. young model constructor

Running model of a paddle steamer. The model of a river paddle steamer looks just as advantageous as compared to the model of a modern passenger liner how a large-scale copy of a steam locomotive is more attractive than a copy of a modern railway locomotive. And on the water the running model of the 19th century "wheel" looks simply amazing - the abundance of superstructures "masts, pipes, efficient things - all this creates an indescribable flavor of the century of steam.

We bring to the attention of ship modelers a model of a paddle steamer "BURLAK" - similar cargo and passenger ships at the end of the 19th century were widespread on the rivers of Siberia. The length of this steamer was 48 m, width - 8.25 m and draft with full load - 1.25 m. Paddle wheels, driven by a steam engine with a power of 120 hp, provided the steamer with a speed of about 10 versts per hour.

The hull of the vessel was recruited from rectangular frames with rounded zygomatic parts. In the rear of the hull, there was a steering wheel, consisting of a wooden feather, fixed in a forged steel frame. The feather was attached to the crinoline with a chain sorlin.

In the bow of the vessel, a manual anchor and mooring spire was installed, which was used to haul out the sheima (anchor chain) and mooring ropes. Anchors of the Admiralty type with steel rods were attached to the steamer in a marching manner - on fish beams with hoists and hooks. There, in front of the spire, a bollard was fixed, intended for towing the vessel. Mooring bollards were located two on each side - in the bow and stern of the vessel.

1 - electric motor MU-30; 2 - gearbox mounting (M5 bolt with nut); 3 - gearbox housing (duralumin, sheet s4); 4 - fastening the gearbox cover (bolt M5 with nut); 5 - primary gear wheel of the reducer; 6 - a gear wheel of the first stage; 7- gear wheel of the second stage; 8 - intermediate shaft; 9,17 - intermediate shaft bearing bushings (bronze); 10 - gear cover (duralumin, sheet s4); 11.16 - propeller shaft bearing bushings (bronze); 12 - propeller shaft (steel); 13,15 - spacer sleeves (steel); 14 - a gear wheel of the second stage

The steamer was driven by rowing wheels partially submerged in water. Each of the wheels consisted of a hub, rings and spokes - eight wooden slabs were fixed between the latter. At deck level, the paddle wheels were edged with rails; from above, the wheels were covered with side metal casings. Open navigation bridges were installed on top of the casings. Service premises were also built on the ramparts.

In the central part of the ship, between the paddle wheels, there was an engine room, and behind it was a boiler casing.

Passenger cabins of the first and second classes were located on the deck. In the forward part of the ship, above the cabins, a promenade deck was arranged; benches were installed along the railing, three on each side. Two ladders were intended to enter the promenade deck. The wheelhouse was located in the central part of the vessel.

Behind the aft cabins there was a tiller drive compartment, closed from above by a wooden grate; The drive rods were led into the wheelhouse along boxes, along the right and left sides.

It is not too difficult to make a model of the Burlak steamer. The recommended scale is 1:50, while the length of the "wheel" will be 960 mm - this will be quite enough for both a running model (with or without radio control) and a bench model.

Almost all parts of the hull and superstructures can be made of birch plywood with a thickness of 3 to 5 mm. Rowing wheel discs are also cut from 3-mm plywood, plates are cut from beech slats, and the hubs are turned from birch. All plywood elements are assembled with epoxy glue; after its polymerization and cleaning, the prepared assembly units are covered with parquet varnish.

A deck is glued into the finished hull, made entirely with rafters of 4 mm plywood. The deck should be provided with cutouts for superstructures (through which access to the model's power plant and radio equipment is provided), as well as for paddle wheels. Paddle wheel guards are cut from 0.5 mm thick aluminum sheet.

On the deck of the model, bow and stern mooring bollards are fixed, anchor device, as well as an anchor and mooring capstan. A chimney is installed behind the wheelhouse - it is best to solder its body from 0.3 mm thick tinplate. The bases of the ventilation deflectors can be made of the same material, and the air intakes for them can be made of plastic balls from children's toys that are suitable in diameter.

1 - flagpole; 2 - aft cabins; 3 - towing arch; 4 - transition ladder; 5 - towing hook; 6- chimney; 7 - steam whistle; 8 wheelhouse; 9 - paddle wheel casing; 10 - lifebuoy; 11 - guard rail; 12 - promenade deck; 13 - cables; 14 - mast; 15 - bow cabins; 16 - vestibule of the entrance to the bow rooms; 17 - porthole; 18 - headstock; 19 - mooring bollard; 20 - admiralty anchor; 21- towing bollard; 22 - anchor chain (sheima); 23 - anchor and mooring capstan; 24 - rectangular porthole; 25 - fenders; 26 - wooden fender; 27 - paddle wheel; 28 - enclosure brackets; 29 - grill over the tiller drive; 30 - rudder feather; 31 - open bridge; 32 - side light; 33 - ladder; 34 - ventilation deflector; 35 - overhang superstructure; 36 - bench; 37 - rack with fire buckets; 38 - trash, 39 - fishblock. Separate elements of the steamer model

The power plant of the ship model is made on the basis of the MU-30 electric motor (its operating voltage is 27 V, current consumption is 5 A, power is 40 W, rotation speed is 7500 rpm). To drive the paddle wheels, a home-made two-stage gearbox with a gear ratio of about 20 is used, which provides a paddle wheel speed of 375 rpm.

Of course, it is difficult to make gear wheels on your own in a home workshop, therefore, the design of the gearbox will have to start with the selection of two cylindrical gear pairs with a module of 1.5 - 2 mm and with gear ratios of 4 and 5. Parts of the gearbox housing are cut from sheet duralumin, steel shafts, Turned, pinions and cogwheels are pressed onto them and fixed with 1 mm pins, which provides reliable protection against twisting. Bronze bushings pressed into the base and housing cover are used as plain bearings.

Recommended color of the steamer model: hull below the waterline, rudder blade and paddle wheels - red: side above the waterline, bulwarks, bollards, spire, anchor chains, anchors, ventilation deflectors and fenders - black; mast, superstructures, casing of rowing wheels above the bulwark, fish-beam, wheelhouse, name of the ship, lifebuoys, guard rails, awning, vestibule, racks, rack and fire buckets, as well as benches - white; ladders, decks, overlappings of side superstructures, paddle wheel casings and fenders - light gray; doors, frames of rectangular windows of superstructures and deckhouses - natural wood.

Czech magazine "ABC" The topic offered today to the attention of ship modelers, I think, will interest copyists of all levels, from schoolchildren who build contour rubber motor "upright", and ending with experienced radio operators. The fact is that we propose a steamer with paddle wheels for reproduction in miniature - there is no need to tell in detail about the “deliciousness” of such work.

One of the most elegant river steamers of the last century, Bohemia, built in 1841, was chosen as a prototype for copying. Together with showiness appearance this ship is also characterized by comparative simplicity, which does not harm the copy version of the model.

A copy of "Bohemia" can be made not only for use in various sports classes, but also in different designs. So, for example, the hull of a rather large elongation with various contours of the bow, central and stern parts is well reproduced both in the classic version with a frame set and sheathing of precisely fitted linden or balsa slats, and in a shell, made of fiberglass on a blank. It is not a sin to recall such an option as the execution of a whole body from a single block of wood, followed by gouging until a wall thickness of 2-3 mm is obtained, followed by the installation of sparsely spaced frames. Despite the exaggeration of this technology, which is more typical of school ship models, when copying “Bohemia” with its wide low body, such a technique is quite justified, even if a high-quality model is created.

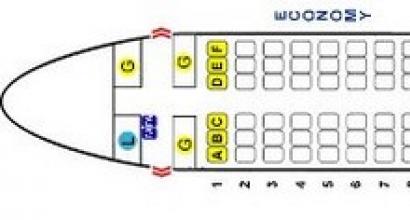

Having determined the scale of copying, it is necessary to draw the main projections of the model in full size and compose the “stuffing” of the body. To help those who think about doing such a micro-steamer, we present the layout of the most complex option - a model only 720 mm long, with radio control. As you can see in the figures, even with such a small size, all nodes are located in the case quite freely, so when creating a larger copy, problems should not arise at all.

At this scale, the deck is easiest to make one-piece by gluing a blank for it from individual pine or linden laths with a cross section of 2x4 mm. The drive of the model - from a conventional non-boosted electric motor for a voltage of 3-4.5 V - is quite sufficient in power for a large-scale travel speed. The gear reducer, unlike the prototype, is still better placed inside the housing. It should have a gear ratio of the order of 1:10. The single shaft of the paddle wheels is made of steel wire with a diameter of 4 mm and, on the copy, passes through two bronze bearings installed in the side bosses directly below the deck.

The materials for the manufacture of the paddle wheels themselves can be very different. Let's name only two main options: solid wood, using plywood "rims", slats and plates, and all-metal. In the latter case, in addition to steel or brass wire, you will need to find more suitable sheet blanks for rowing plates. Likewise, different designs are permissible when working on the rudder and above its drive.

Superstructures and all deck assemblies are best mounted tightly. Celluloid should be recognized as the main material for volumetric superstructures, although "boxes" will turn out to be not much worse from plywood, textolite or even cardboard (the latter will have to be soaked through with warm drying oil). Fences and awning posts are made of wire and assembled by soldering. For small parts, the easiest work and good appearance will be provided by using solid wood. The final appearance will depend on the quality of the finish, lacquer and paint. The case in the slotted version is impregnated with linseed oil or liquid two-component parquet varnish, after which it is painted.

The driving characteristics of the miniature “Bohemia” are very good. True, it must be admitted that for such a copy it is still better to have a water surface with a small wave. After the start, the model accelerates quickly and, despite the large lengthening of the body, responds quite “briskly” to steering deflections. At the specified copying scale, the weight of a fully completed model should be within 1000-1100g.

DESCRIPTION OF THE BOHEMIA STEAMER

The ship's hull is divided by bulkheads into the following compartments (starting from the bow): an open bow compartment with a length of 5.35 m, a galley - 1.5 m, a second-class saloon - 6.3 m, crew cabins and storage rooms - 3.3 m, engine room compartment and boiler room - 5.85 m, crew cabins - 1.5 m, ladies' room (cabin) - 3.6 m, first class passenger compartment - about 10.6 m. ... The deck was used for walking passengers - if necessary, benches were installed on it. The rear of the deck could be covered with a canvas awning pulled over the side racks.

The hull of the steamer, the superstructure and the casing of the paddle wheels are made of wood: only the side and bottom frames were made of iron corner profiles. As can be seen from the above figures, "Bohemia" had an unusually elongated hull with an almost rectangular cross-section in its central part and rounded contours in the bow and stern. The coefficient of displacement completeness is 0.65. The front part of the keel curved elegantly upward, forming at the end the base for the installation of the nasal figure - a silver-painted Czech lion with a golden royal crown on its head. The total length of the bow figure was approximately 0.9 m. The aft hull is steep. She carried a 1.6 m long rudder plate suspended on three hinged hinges.

Bohemia was equipped with a two-cylinder steam engine with oscillating cylinders, vertically arranged. The cylinder diameter was 0.525 m and the stroke was 0.725 m. At 40 rpm, the engine developed a power of 37.5 kW (51 hp). The steam engine was supplied a steam condenser and a reversing system. It was made in England and was very perfect for its time. It is interesting that after Bohemia, this machine served for a long time on another steamer, and there are assumptions that it works to this day on a steamer. " Disbar ”.

The steam boiler was manufactured by the same company that built the steam engine. The working pressure of steam is 1.33 atm. Inside a boiler with three furnaces with a combustion area of about 35 m 2, 165 copper pipes with a diameter of 54 mm were placed, connected in three bundles. The products of fuel combustion passed between these tubes, heated the water and were discharged into the atmosphere through a chimney with a height of about 4.5 m. low bridges. The system of lowering and raising the pipe is a chain hoist, using blocks and ropes going to a folding mast.

The steam engine rotated the side paddle wheels through a gear transmission with a gear ratio of 1: 1.5, and the drive gears were located outside the housing in the volumes of the paddle wheel housings. The iron rims of the paddle wheels had an outer diameter of about 4.1 m and the lower edge was equal to the level of the lower point of the bottom of the hull. Twelve paddle blades on each wheel were screwed to the metal spokes, their size was 0.35x1.6 m. The casing with an outer diameter of 2.15 m and a width of 1.95 m had waterproof walls, except for the outer ones, which were wooden lattices.

The wooden steering wheel was driven by cables running from the steering wheel through a pulley system. On the axle of the wheel, the diameter of which was equal to 1.5 m, there was a driving drum with a cable. For the helmsman, a special platform was equipped, which allowed him to have a forward view of the water area.

An anchor of the Admiralty type with a length of about 1.2 m was lifted by hand and in the stowed position lay freely on the starboard side of the front of the hull.

To carry the flag and place the chimney folding mechanism in the front of the steamer, a large mast with a height of 9 m was installed. It also folded back, for which two cables were used, going from the mast forward and to the left side. To carry the stern flag, a rigid flagpole was installed in the rear of the hull, the height of which is 3.3 m.

The rear passenger compartment (first class) was illuminated with five windows on each side, the front (second class) - with two pairs of windows. Each of them was a three-section opening with glass with a total size of 0.6x1.8 m. Two windows were located on the front wall of the hull to illuminate the galley; skylights were installed above the engine room and crew cabins. The captain's bridge with rigid handrails was mounted between the casings of the paddle wheels - a ladder led from the deck to it. In front of the deck there was a conductor's bench, in front of which a bell was suspended on a curved bracket. In the same place, there was a chimney from the galley and a pipe for removing steam from the boiler safety valve.

The side hull plating was protected by four overhead strips. The lowest one was located almost above the waterline; the next one ran along the lower edge of the windows, and along their upper edge - another bar. The fourth, the last, walked along the edge of the deck.

During the crossing of Czech territory, a red flag with narrow white horizontal edges and a silver Czech lion in the middle was hoisted from the stern flagpole. On the territory of Hungary, the flag was replaced by red-white-red with a shield image. The mast carried a long white-red-white pennant with the name of the steamer in white. A small Hungarian emblem (two-headed eagle with a shield) was located on the inner walls of the paddle wheel housings.

The bottom of the hull and the underside of the port, including the bottom trims, were dark brown. The strip between the windows, window frames, deck enclosures of entrances, paddle wheel casings (excluding grilles), overhangs, fences, mast, flagpole, skylight hulls were painted white. Red: top three rows of cover bars and paddle wheels. Black was the anchor, the upper deck casing of the steam boiler, all chimneys and parts of the frames visible in the open front of the hull. The deck, the captain's bridge, the conductor's bench, the steering gear with the bridge and the rudder blade were of the color of natural wood impregnated with linseed oil. The paddlewheel grilles and stripes at the top and bottom of the portholes were painted dark green.

The hull of this steamer model is a flat streamlined plate. The front end has a sharpening, traditional for ships and boats, which reduces water resistance when moving forward, and the aft part of the hull is simply cut in the transverse direction. The tin rudder is installed here.

The easiest way to attach it is by cutting into a previously made slot in the stern. By bending or bending it, you can launch the boat in a circle or change direction. In the front and rear parts of the hull, two studs are driven in: these are support pins, on which the deck is installed. On the sides of the hull of the steamer, wide cutouts are made - for the blade propeller.

Paddle Steamer Model Propulsion

It is installed on two flat brackets made of sheet metal attached to the cutouts. The propeller consists of two wheels with blades and an axle. The wheel hubs are two wooden rounds (or plugs), along the circumference of which slots are cut for the blades made of tin. The wheels are protected by tin arcs attached to the body cutouts.

To drive the wheels into rotation, a rubber motor is mounted on the body. For him, pulleys (rollers) are installed along the centerline of the body in its front and rear parts, through which a thin elastic band is pulled. One end of it is attached to the front of the body, and the other - to the axis of the blade propeller.

By rotating the latter, the rubber band is wound on its axis: this is how the rubber motor starts. If you let go of the wheel now, the rubber band will begin to unwind, driving the wheels with blades through the axle into rotation.

Deck of a paddle steamer model

It is hollow to cover all protruding parts of the body. Cut out of tin. Figure 1 shows a steamer deck pattern: at the cut out blank, the shaded places are folded back - from them the bow and stern parts of the deck are formed.

At the places marked on the pattern with a dotted line, the deck superstructure itself is installed. It can also be made of tin; but it is easier to assemble it from wooden elements: a flat plank platform, a cabin and two pipes (really from pipes or pieces of a round wooden rod). Styrofoam can be used as an affordable and convenient material for superstructure elements.

Any pencil can serve as a mast for this steamer, and harsh black threads can serve as stretch marks. The deck is installed on the pins of the hull intended for it and additionally rests with its cutouts on the sides on the axis of the propeller.

Painting of a paddle steamer model

The wooden blank of the model body is best protected from getting wet by oil paint. It can be applied with a brush, in two layers: the first is the most liquid, for better impregnation of the wood surface, and the second - of normal consistency, of any color: after all, the hull is practically invisible from under the shell of the deck.

To paint the rest of the elements of the steamer model, it is convenient to use aerosol cans, and the paint can be different: the boat will turn out more elegant, more beautiful. Aerosol coating is easier to apply, adheres better to any material - both metal and wood, forming a thin and light paint layer that is not burdensome for a small model.

Each element of the model can be coated with paint separately, as it is manufactured, that is, even before assembly. However, if it is decided to finally paint the model after assembly in one color, the preliminary element-by-element coating of the parts can be omitted and use an aerosol can already on the finished model.

Launching a paddle steamer model

Preparation for launching the boat comes down mainly to pulling the rubber motor. To do this, it is not necessary to raise the deck: the rubber motor is accessed from the outside, through the propeller. It is enough to take the model in your left hand, and insert your right index finger between the propeller blades and rotate it. Z

you need to spin the propeller at any position of the boat in the hand from its bow - then the rubber motor will spin the blades in the right direction. Then, holding the propeller blades with your left hand, lower the model into the water so that they are immersed in the water: you can, by adjusting the rudder to the desired course, release the boat on its maiden voyage. Its range will depend on the degree of spin of the rubber motor.

Rice. 1. Model of a paddle steamer: 1-deck; 2- deck superstructure with chimneys and wheelhouse; 3 - case; 4 - support pin (1x25.4 pcs.); 5 - impeller hub; 6-blade; 7 - rubber motor (L650); 8 - wheel guard arc; 9 - cutout of the body for the propeller; 10-wheel; 11 rubber motor pulleys (2 pcs.); 12 - rubber motor fixing pin (L15); 13 - wheel bracket. A - deck pattern

Rice. 2. Installation diagram of the rubber motor: 1-propeller bracket (2 pcs.); 2-mover; 3 - propulsion guard; 4 - elastic band; 5 - pulleys (rollers); 6 - the axis of the mover; 7 - steering wheel

We bring to the attention of ship modelers paddle steamer model"BURLAK" - similar cargo and passenger ships at the end of the 19th century were widespread on the rivers of Siberia. The length of this steamer was 48 m, width - 8.25 m and draft with a full load - 1.25 m.

Rowing wheels, driven into rotation by a steam engine with a capacity of 120 hp, provided the steamer with a speed of about 10 versts per hour. The hull of the vessel was recruited from rectangular frames with rounded zygomatic parts. At the rear of the hull, there was a steering wheel, consisting of a wooden feather, fixed in a forged steel frame. The feather was attached to the crinoline with a chain sorlin.

In the bow of the vessel, a manual anchor and mooring spire was installed, which was used to haul out the sheima (anchor chain) and mooring ropes. Anchors of the Admiralty type with steel rods were attached to steamer in a marching way - on fish beams with hoists and hooks. There, in front of the spire, a bollard was fixed, intended for towing the vessel. Mooring bollards were located two on each side - in the bow and stern of the vessel.

The steamer was driven by rowing wheels partially submerged in water. Each of the wheels consisted of a hub, rings and spokes - eight wooden slabs were fixed between the latter. Deck level rowing wheels were edged with drapes; from above, the wheels were covered with side metal casings. Open navigation bridges were installed on top of the casings. Service premises were also built on the ramparts.

In the central part steamer, between the paddle wheels was the engine room, and behind it was the boiler casing. Passenger cabins of the first and second classes were located on the deck. In the forward part of the ship, above the cabins, a promenade deck was arranged; benches were installed along the railing, three on each side. Two ladders were intended to enter the promenade deck.

The wheelhouse was located in the central part of the vessel. Behind the aft cabins there was a drive compartment, closed from above by a wooden grate; The drive rods were led into the wheelhouse along boxes, along the right and left sides. To make steamer model"Burlak" is not too difficult.

The recommended scale is 1:50, while the length of the "wheel" will be 960 mm - this will be quite enough for both a running model (with or without radio control) and a bench model. Almost all parts of the hull and superstructures can be made of birch plywood with a thickness of 3 to 5 mm. Rowing wheel discs are also cut from 3-mm plywood, plates are cut from beech slats, and the hubs are turned from birch. All plywood elements are assembled with epoxy glue; after its polymerization and cleaning, the prepared assembly units are covered with parquet varnish.

A deck is glued into the finished hull, made entirely with rafters of 4 mm plywood. The deck should be provided with cutouts for superstructures (through which access to the model's power plant and radio equipment is provided), as well as for paddle wheels.

Paddle wheel guards are cut from 0.5 mm thick aluminum sheet. On the deck of the model, bow and stern mooring bollards, an anchor device, and an anchor and mooring spire are fixed. A chimney is installed behind the wheelhouse - it is best to solder its body from 0.3 mm thick tinplate.

The bases of the ventilation deflectors can be made of the same material, and the air intakes for them can be made of plastic balls from children's toys that are suitable in diameter. The power plant of the ship model is made on the basis of the MU-30 electric motor (its operating voltage is 27 V, current consumption is 5 A, power is 40 W, rotation speed is 7500 rpm). To drive the paddle wheels, a home-made two-stage gearbox with a gear ratio of about 20 is used, which provides a paddle wheel speed of 375 rpm.

Of course, it is difficult to make gear wheels on your own in a home workshop, therefore, the design of the gearbox will have to start with the selection of two cylindrical gear pairs with a module of 1.5 - 2 mm and with gear ratios of 4 and 5. Parts of the gearbox housing are cut from sheet duralumin, steel shafts, Turned, pinions and cogwheels are pressed onto them and fixed with 1 mm pins, which provides reliable protection against twisting.

Bronze bushings pressed into the base and housing cover are used as plain bearings. Recommended color steamer models: hull below the waterline, rudder blade and paddle wheels are red; board above the waterline, bulwarks, bollards, spire, anchor chains, anchors, vents and fenders - black; mast, superstructures, casing of rowing wheels above the bulwark, fish-beam, wheelhouse, name of the ship, lifebuoys, guard rails, awning, vestibule, racks, rack and fire buckets, as well as benches - white; ladders, decks, overlappings of side superstructures, paddle wheel casings and fenders - light gray; doors, frames of rectangular windows of superstructures and deckhouses - natural wood.

I. TEREKHOV

Goods and passenger paddle steamer"BURLAK": 1 - flagpole; 2 - aft cabins; 3 - towing arch; 4 - transition ladder; 5 - towing hook; 6 - chimney; 7 - steam whistle; 8 - wheelhouse; 9 - paddle wheel casing; 10- lifebuoy; 11 - guard rail; 12- promenade deck; 13- guys; 14 - mast; 15 - bow cabins; 16 - vestibule of the entrance to the bow rooms; 17 - porthole; 18 - headstock; 19 - mooring bollard; 20 admiralty anchor; 21 - towing bollard; 22 - anchor chain (sheima); 23 - anchor and mooring capstan; 24 - rectangular porthole; 25 - fenders; 26 - wooden fender; 27 - paddle wheel; 28 - enclosure brackets; 29 - grill over the tiller drive; 30 - rudder feather; 31 - open bridge; 32 - side light; 33 - ladder; 34 - ventilation deflector; 35 - overhang superstructure; 36 - bench: 37 - rack with fire buckets; 38 - trash, 39 - fishblock. On right - individual elements steamer models

Power plant of the steamer model: 1 - MU-30 electric motor; 2 - gearbox mounting (M5 bolt with nut); 3¬¬¬¬¬¬ ¬¬- gearbox housing (duralumin, sheet s4); 4 - fastening the gearbox cover (bolt M5 with nut); 5 - primary gear wheel of the reducer; 6 - a gear wheel of the first stage; 7 - gear wheel of the second stage; 8 intermediate shaft; 9,17 - intermediate shaft bearing bushings (bronze); 10 - gear cover (duralumin, sheet s4); 11.16 - propeller shaft bearing bushings (bronze); 12- propeller shaft (steel); 13,15 - spacer sleeves (steel); - gear wheel of the second stage

A seafarer lives in the soul of every boy, so any stream of rain is already a river, and a large puddle is a whole sea that calls to launch boats - from the simplest, from a chip or sheet of paper, to specially carved, and even more so combined, as offered by a German magazine " Technium "self-propelled steamer model. Yes, not an ordinary steamer, but an old, two-pipe, with paddlewheels on the sides. What kind of child does not want to build one, especially since its design is quite accessible for independent reproduction.

Indeed, all the parts are so simple that they can be made and assembled in one evening. Judge for yourself. The model essentially consists of two large parts: a hull with a propeller and a deck superstructure. And what components they are subdivided into - let us consider in more detail.

Frame

It is a flat streamlined plank. The front end has a sharpening, traditional for ships and boats, which reduces water resistance when moving forward, and the aft part of the hull is simply cut in the transverse direction. The tin rudder is installed here. The easiest way to attach it is by cutting into a previously made slot in the stern. By bending or bending it, you can launch the boat in a circle or change direction.

In the front and rear parts of the hull, two studs are driven in: these are support pins, on which the deck is installed. On the sides of the body there are wide cutouts - for the blade propeller.

Mover

It is installed on two flat sheet metal brackets attached to the cutouts. The propeller consists of two wheels with blades and an axle. The wheel hubs are two wooden rounds (or plugs), along the circumference of which slots are cut for the blades made of tin. The wheels are protected by tin arcs attached to the cutouts of the body.

Rice. 1. Model of a paddle steamer (click to enlarge): 1 - deck; 2-deck superstructure with chimneys and wheelhouse; 3 - case; 4 - support pin (1x25.4 pcs.); 5 - impeller hub; 6 - blade; 7 - rubber motor (L650); 8 - wheel guard arc; 9 - cutout of the body for the propeller; 10 - steering wheel; 11 - rubber motor pulley (2 pcs.); 12 - rubber motor fixing pin (L15); 13 - wheel bracket. A - deck pattern

To drive the wheels into rotation, a rubber motor is mounted on the body. For him, pulleys (rollers) are installed along the centerline of the body in its front and rear parts, through which a thin elastic band is pulled. One end of it is attached to the front of the body, and the other - to the axis of the blade propeller. By rotating the latter, the rubber band is wound on its axis: this is how the rubber motor starts. If you let go of the wheel now, the rubber band will begin to unwind, driving the wheel with blades through the axle into rotation.

Deck

It is hollow to cover all protruding parts of the body. Cut out of tin. Figure 1 shows the deck pattern: at the cut out workpiece, the shaded places are folded back - from them the bow and stern parts of the deck are formed.

At the places marked on the pattern with a dotted line, the deck superstructure itself is installed. It can also be made of tin; but it is easier to assemble it from wooden elements: a flat plank platform, a cabin, and two pipes (really from pipes or pieces of a round wooden rod). Styrofoam can be used as an affordable and convenient material for superstructure elements. Any pencil can serve as a mast, and harsh black threads can serve as stretch marks.

The deck is installed on the pins of the hull intended for it and additionally rests with its cutouts on the sides on the axis of the propeller.

Coloration

The wooden blank of the model body is best protected from getting wet by oil paint. It can be applied with a brush, in two layers: the first is the most liquid, for better impregnation of the wood surface, and the second - of normal consistency, of any color: after all, the hull is practically invisible from under the shell of the deck.

To paint the rest of the model's elements, it is convenient to use aerosol cans, and the paint can be different: the boat will turn out to be more elegant, more beautiful. Aerosol coating is easier to apply, adheres better to any material - both metal and wood, forming a thin and light paint layer that is not burdensome for a small model.

Rice. 2. Diagram of the installation of the rubber motor (click to enlarge): 1 - the propeller bracket (2 pcs.); 2 - mover; 3 - propulsion guard; 4 - elastic band; 5 - pulleys (rollers); 6 - the axis of the mover; 7 - steering wheel

Each element of the model can be coated with paint separately, as it is manufactured, that is, even before assembly. However, if it is decided to finally paint the model after assembly in one color, the preliminary element-by-element coating of the parts can be omitted and use an aerosol can already on the finished model.

Model start

Preparation for launching the boat comes down mainly to pulling the rubber motor. To do this, it is not necessary to raise the deck: the rubber motor is accessed from the outside, through the propeller. It is enough to take the model in your left hand, and insert your right index finger between the propeller blades and rotate it. You need to spin the propeller at any position of the boat in your hand from its bow - then the rubber motor will spin the blades in the right direction.