Where do dry superjet. Made by us

The Sukhoi Superjet 100 (English designation is similar to the Sukhoi SuperJet 100) is a short-haul passenger aircraft developed by Sukhoi Civil Aircraft Closed Joint Stock Company. Operated from 2011 to the present.

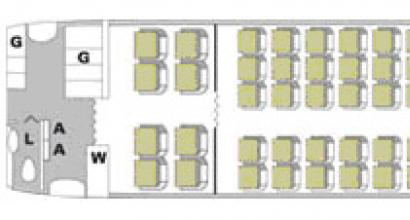

Overview of the cabin layout and the location of the best seats

Salon "Superjet" has 87 seats: 12 business class and 75 - economy class. Of course, business class seats are the most comfortable for flying, as the seats here are somewhat wider and softer. However, it should be noted that the business class is separated from the noisy economy class cabin by a rather thin partition, so it will not be possible to completely soundproof business class passengers. The best seats in both business and economy class are the seats of the very first row (1st and 6th rows, respectively), so it is advisable to book them when buying. Here, no one will recline the back of the chair in your direction, there is legroom. Yes, and to be a little further from the noisy middle of the economy class - sometimes very nice. After the first row seats, the best in the cabin, of course, are the seats at the windows (with the letters A and F according to the diagram). The windows in the aircraft are large, conveniently located and with a good view.

Not the best choice are the seats under the letters C and D. This is due to the fact that they are located at the very aisle, which is not wide enough. The constant movement of passengers to the toilet or stewards with carts create some inconvenience. The most unfortunate seats in the Sukhoi Superjet 100 cabin are the seats in the back row (entire row number 20 according to the diagram), especially seats C and D, adjacent directly to the aisle. One of the main reasons for this is regular queues for the toilet. This may cause additional inconvenience.

Aircraft device

In scientific terms, the Sukhoi Superjet 100 (its ICAO designation is SU95) is a turbofan, twin-engine, low-wing swept-wing, single-fin tail unit. The wing profile is supercritical with single-slotted flaps (that is, flaps made in the form of simple rotary). It should be noted that part of the wing mechanisms, as well as its fairings, as a rule, are made of special composite materials, which significantly increases their strength, rigidity and wear resistance.

It is also noteworthy that the designers of the "Superjet" were the first in Russia to use the side control stick ("sidestick") instead of the traditional steering wheel. This solution is very innovative for the domestic aircraft industry. Another fairly recent solution is that the aircraft uses an algorithmic protection system that prevents the aircraft from touching the runway, instead of mechanical shock absorbers.

The production cost of a Sukhoi Superjet 100 unit is US$27 million (as of 2019).

History of creation

The date that marked the beginning of the development of the Sukhoi Superjet 100 is March 11, 2003, when the company's expert council named the PRJ project the winner. The development of the aircraft was completed by the beginning of 2006, and already in February of the same year, the assembly of the first aircraft with the number 97002 began. Less than a year later, in early 2007, static tests of the first PRJ started at TsAGI. September 26, 2007 was the presentation of the aircraft.

Testing of the aircraft, as well as its production, began in 2008. On February 20, the first race of Sukhoi Superjet 100 engines was carried out, which gave positive results. On May 14, tests were carried out for running and taxiing on the runway, and on the 19th the aircraft made its first flight. In October 2008, factory tests of the aircraft were fully completed, and the process of certification of the Superjet at the International Aviation Committee began. In November of the same year, life tests of the machine began. In June 2009, the aircraft took part in the international air show in Le Bourget.

The start of operation of the aircraft began on April 21, 2011 and continues to the present.

Overview of the SuperJet 100 family

- The Sukhoi SuperJet 100 is the first aircraft of the SuperJet 100 family. As mentioned above, this is a short-haul passenger aircraft with two turbofan engines and a supercritical wing.

- "Sukhoi Superjet 100LR" ("Sukhoi SuperJet-100-95LR") is a modification of the "Superjet" (LR - Long Range) with an increased flight range (up to 4578 km, the largest among all aircraft of the family) and a slightly increased maximum takeoff weight. The first flight of the SuperJet-100-95LR took place in February 2013. To date, the Sukhoi SuperJet-100-95LR is also actively used.

- "Dry Superjet 100SV" ("Sukhoi SuperJet-100-95SV") - a modification of the "Superjet" with an elongated fuselage (SV - Stretched Version). Large passenger capacity is expected, as well as takeoff weight. The design of the new model began in 2019, and it is planned to complete the development in 2019.

In total, as of April 2019, the number of Superjet aircraft built was increased to 109, of which 91 were handed over to customers. Among the operators of the Sukhoi Superjet 100 are such countries as Russia, Mexico, Ireland, Armenia, Laos, Indonesia and Thailand.

Flight performance of the SuperJet 100 family:

| Model | SuperJet 100-95 | SuperJet 100-95LR |

| Length | 29.94 m | |

| Height | 10.28 m | |

| Wingspan | 27.80 m | |

| Fuselage diameter | 3.24 m | |

| Maximum takeoff weight | 45880 kg | 49450 kg |

| Maximum landing weight | 41000 kg | 12245 kg |

| Empty weight | 24250 kg | |

| Bearing surface area | 77 m2 | |

| Cruising speed | 830 km/h / 0.78M | |

| Max speed | 860 km/h / 0.81M | |

| flight altitude | 12200 m / FL400 | |

| Engines | 2 × SaM146-1S17 | 2 × SaM146-1S18 |

| Maximum thrust | 2×76.84 kN | 2×79.00 kN |

| in takeoff mode | ||

| Range of flight | 3048 km | 4578 km |

| Crew | 2+2 | |

| Passenger capacity | 98 in basic configuration (up to 108) | |

| passenger doors | 4 | |

| The volume of luggage compartments | 21.7 m3 | |

| Takeoff run | 1731 m | 2052 m |

| Run length | 1630 m | |

| Fuel supply | 15805 l | |

| Auxiliary power unit | Honeywell RE220 | |

| The first flight | May 19, 2008 | February 12, 2013 |

Advantages of the aircraft

One of the main advantages of the Superjet is the use of the latest technologies and design solutions in its design, which have seriously affected its efficiency and reliability. When developing the aircraft, the requirements of such organizations as the FAA (Federal Aviation Administration) and EASA (European Aviation Safety Agency) were taken into account, which allowed the Sukhoi Superjet 100 to be certified in accordance with international standards. It should also be noted that during the development of the Superjet, all the wishes of its potential customers (and not only Russian ones) were taken into account and analyzed, which made it possible to maximally adapt it to future operating conditions.

One of the indisputable advantages of this aircraft is the fact that the runways of airfields of all classes (A, B and C) are quite suitable for its use. This is largely achieved not only due to the design features of the Superjet, but also due to the modern avionics system, which, among other things, allows the aircraft to land in difficult meteorological conditions. The cost of a plane ticket is relatively low, which is definitely its serious advantage.

The LR modifications made it possible to increase the flight range of the Sukhoi Superjet 100. And another advantage of the aircraft is its low operating cost, as well as a high level of weight and aerodynamic perfection.

Aircraft Disadvantages

It is worth noting that the first and main design flaws of the Sukhoi Superjet 100 were identified and eliminated at the testing stage and in the first two years of operation (from 2011 to 2013).

Now the main disadvantages of the aircraft are mainly domestic inconveniences. As noted above, this is not a wide enough passage and some "noise" in the cabin, creating certain difficulties for passengers in "unfortunate" places. An inconvenience for the business class is a relatively thin partition separating this compartment from the economy class.

Nevertheless, it is worth noting that the aircraft has an unprecedented security system, and this, of course, is able to compensate for all the household interference listed above.

Conclusion

Despite all its shortcomings, the Sukhoi Superjet 100 is a good aircraft that is suitable for both short-haul flights and long-haul flights (thanks to the LR modification). The cabin, although smaller compared to such giants as the Airbus A-380, is nevertheless roomy for this type of machine. An effective security system, as well as modern avionics, make the aircraft one of the most reliable in its class. Turbofan engines PowerJet SaM146 (CM146), installed on the aircraft, have better efficiency and reliability compared to many analogues. Composite materials used in the production of aircraft wings provide rigidity and wear resistance of its structure. The production cost of the aircraft compared to competing models of the same class is definitely lower. In a word, the Sukhoi Superjet 100 is indeed a step towards a new generation of passenger aircraft, both in terms of economy, safety and performance, which makes it one of the best in its class.

If you have any questions - leave them in the comments below the article. We or our visitors will be happy to answer them.

The fate of the first Russian passenger aircraft developed after the collapse of the USSR, the Sukhoi SuperJet 100 (SSJ100), seems to remain bleak. For all the years that the aircraft has been in operation, none of the airlines using the SSJ100 has been able to achieve any tangible economic efficiency from it.

In 2016, the average flight time of the Sukhoi SuperJet 100 was 3-3.7 hours per day, which is three times lower compared to foreign aircraft operated in Russia.

According to the Vedomosti newspaper, citing its own informed sources, the main operator of the SSJ100 - Aeroflot - half of the SSJ100s in the fleet do not take off, which is why the airline has to change the route network. At the same time, the average flight time of Aeroflot on the SSJ100 is just over 3 hours per day.

Things are not going well with the Sukhoi SuperJet 100 from the second largest operator of this aircraft in Russia, Gazpromavia. His SuperJet flies an average of about 2.1 hours a day.

As for the main foreign buyer of the SuperJet, the Mexican airline Interjet, it managed to bring the average daily flight time to 5-6 hours.

However, even these figures cannot be compared with foreign-made aircraft. For Russian airlines last year it was about 9 hours a day, and for foreign low-cost airlines and even more - 12-13 hours.

What is the reason?

According to a Vedomosti source, the main reason for such a deplorable situation is the high cost and difficulty in obtaining spare parts. Due to the small total number of SSJ100s, only UAC factories produce spare parts for them. But since the main goal of the UAC is the fulfillment of the state defense order, the spare parts necessary for the civilian SSJ100 are produced according to the residual principle and they must be waited for a long time.

All this, in turn, affects the economic efficiency of the Sukhoi SuperJet 100, making its operation unprofitable for airlines.

Sukhoi SuperJet will never be of interest to private airlines, - Igor Kuznetsov, a pilot with 20 years of experience, and now an expert consultant in the field of civil aviation, explained to Sneg.TV. - Air transportation is one of the most highly competitive markets in the world. In order for these flights to be profitable, the company's aircraft must be in the sky as much as possible. Sukhoi SuperJet 100 spends most of its time on the ground. Despite the fact that a lot of time and money was spent on the creation of this machine, it still remains quite “raw”, which, in fact, explains the large number of breakdowns.

Because of this, the aircraft is bought very poorly both here and abroad. Airlines see in a nightmare that part of their aircraft turns into "donors", from which spare parts are tritely removed so that another part of the fleet can fly and carry passengers. Unlike Airbus and Boeing, spare parts for which can be ordered and received almost anywhere in the world in a few hours, for Sukhoi it can take weeks. There are practically no parts for them on the market. Third-party manufacturers do not make them, as it is not profitable for them due to the small number of aircraft produced. It also makes no sense to release them anymore, since the demand for the SSJ100 is low, for the reasons stated above. Stories about huge contracts for this aircraft are mostly just words. SSJ100 like to "sell" and "buy" politics, and then mostly only on paper. For operators, as I said, this is a nightmare. So here the circle closes.

regional jet

According to the expert, it's a shame that the SSJ100 occupies a very popular niche in the Russian and foreign markets - inter-regional transportation, where not the worst market opportunities are presented to it. But even in this case, he still has not been able to "prove himself."

In fact, Sukhoi has a fairly good market, - says Igor Kuznetsov. - In the regional segment, it practically does not have to compete with such giants as Airbus and Boeing, which play on a slightly different field.

Its competitors: Bombardier, Embraer, the Dutch Fokker, etc. These companies have significantly lower production volumes compared to the same Airbus and Boeing, which means that their market conditions are much closer to those of the SSJ100.

However, even here we managed to drag out the time of development and creation of the machine to infinity, spend a lot of money on it, for which some Boeing could create a long-haul aircraft from scratch, and after all this, throw it on the market "raw" and already obsolete product.

According to the expert, all this significantly complicates the commercial prospects of the SSJ100, which, most likely, will not be able to get any significant market share.

MS-21

Most likely, it will not be possible to save the SuperJet. In economic terms, it is doomed, although some niche will surely be found for it - the project was too high-profile to be abandoned just like that.

Instead, now it would be worth paying attention to another domestic machine - MS-21. This civil aircraft is quite interesting both technically and economically. And most importantly, they have not yet managed to make as many mistakes with him as they did with Sukhoi. So let's keep our fists for him, - says Kuznetsov.

Recall that just the other day MS-21 made its first test flight in Irkutsk. "The flight went well, as planned," the Irkutsk Aviation Plant said.

Sukhoi Superjet 100 is a new generation short-haul regional 100-seat aircraft that combines the latest technologies in the field of aircraft construction, developed by Sukhoi Civil Aircraft with the wide participation of a number of foreign companies. The certification name of the aircraft is Russian Regional Jet (RRJ), ICAO designation is SU95.

History of creation

The Federal Target Program (FTP) "Development of civil aviation technology in Russia for 2002-2010 and for the period up to 2015", adopted by a decree of the government of the Russian Federation in October 2001, one of the priority tasks was the gradual replacement of old Soviet aircraft with new generation liners. The priority projects in the FTP were the Tu-334 short-haul aircraft and the regional Tu-324. At the time of the adoption of the Program, the short-haul Tu-334 was almost completely ready; A. Tupolev, work was in full swing on the regional Tu-324, which since 2005 was supposed to replace both the morally and physically obsolete Tu-134.

However, unexpectedly for aviation industry specialists, on July 9, 2002, the Russian Aviation and Space Agency (now the Federal Space Agency - Roskosmos) announced a competition for the creation of a promising regional aircraft. The new regional aircraft was mentioned in the Federal Target Program as a distant prospect, because its development was planned to begin only in 2006 and be completed in 2015. In addition, Rosaviakosmos did not have any authority to hold a competition for the development of a civil aircraft, since no one canceled the Decree of the Government of the Russian Federation No. And the very idea of holding a competition under the auspices of Rosaviakosmos was very doubtful, because. Agency officials knew and know the needs of airlines worse than in the Ministry of Transport, which oversees carriers.

The Ministry of Transport of the Russian Federation, represented by Deputy Minister Alexander Neradko, directly stated that the competition was undesirable, which, on the sidelines of the terms of reference for the competitive development of a technical proposal for the creation of a new regional aircraft, the Deputy Minister wrote: "It seems appropriate instead of holding a competition and developing a new regional aircraft, to concentrate the efforts of a limited budget financing for the completion of certification and deployment of Tu-334 production, as well as the development of production of the Tu-204 and Tu-214 family.

And yet, despite the disagreements and inconsistencies in the actions of the Ministry of Transport and officials of Rosaviakosmos, the competition began, and three applications were submitted for participation in it: Tupolev OJSC submitted an application for the Tu-414, EMZ im. V.M. Myasishchev - on the M-60-70 and the Sukhoi Design Bureau - on the RRJ. Since the idea of holding a tender was unexpected, and the deadlines were tight, the projects were probably raw, requiring serious research and improvements. Because of this, the aircraft developed by the plant. Myasishchev almost immediately dropped out of the competition, and the Tu-414 and RRJ remained in the tender.

On March 12, 2003, Rosaviakosmos summed up the results and announced the winner of the Russian Regional Jet (RRJ) project. The decision was expected and it did not cause much surprise among the specialists - the parameters of the terms of reference for the development of the new aircraft largely coincided with the characteristics of the RRJ project. The Sukhoi Design Bureau did not particularly hide the fact that the specialists of TsAGI im. Zhukovsky, who prepared the terms of reference, carefully studied the requirements of the market, conducted numerous surveys of potential customers of the regional aircraft both in Russia and abroad.

At the same time, in early March 2003, in Seattle, the leaders of Sukhoi and Boeing entered into long-term agreements that determined the framework for cooperation under the RRJ program. Boeing specialists are committed to providing consulting assistance and providing their intellectual property for the design, manufacture, certification, marketing, sales, after-sales service of the aircraft family and program management.

Thus, after 2003, all budgetary funds allocated for the development of short-haul aircraft went to the RRJ program, and the practically finished Tupolev Design Bureau aircraft - Tu-334, Tu-324 did not receive further development and were subsequently curtailed. The Tu-334, whose certification and launch into serial production in 2003 used almost all the budgetary funds allocated to support civil aircraft construction, looked obsolete against the background of the RRJ and could hardly compete in terms of technical level with this promising development.

Giving preference to the RRJ, Rosaviakosmos voluntarily replaced the Tupolev time-tested, well-known and reliable family of passenger aircraft with a beautiful idea that existed at that time only on paper. The simplest explanation for this state of affairs is administrative lobbying, because it is no secret that in 2002 the head of Rosaviakosmos, Yuri Koptev, also headed the board of directors of the Sukhoi Design Bureau joint-stock company.

The first steps of the new liner

On February 17, 2006, the assembly of the first RRJ was started in Komsomolsk-on-Amur, a year later, on January 28, 2007, it was delivered to Zhukovsky for static tests at TsAGI.

In June 2007, the United Aircraft Corporation, PJSC Sukhoi Company, the Italian group Finmeccanica, Sukhoi Civil Aircraft and Alenia Aeronautica signed a General Agreement aimed at a Strategic Partnership within the framework of the project to create a family of Sukhoi Superjet 100 aircraft, and announced the creation joint venture. This Agreement determines the acquisition by Alenia Aeronautica of 25% shares + 1 share of Sukhoi Civil Aircraft. In addition, the Agreement stipulates the conditions for the participation of the Italian side in the financing of the program (at least 25% of the total investment in the project).

The deal to acquire 25% + 1 share was closed on April 7, 2009. The total value of the shares acquired by Alenia Aeronautica exceeds USD 183 million (EUR 138 million), making the Sukhoi Superjet 100 project the largest aviation alliance between Russia and Europe.

In 2007, the Italian Alenia Aeronautica and the Russian Sukhoi holding created a joint venture SuperJet International headquartered in Venice, in which Alenia Aeronautica owns 51% and Sukhoi owns 49%. The JV is responsible for marketing and sales of the family aircraft in Europe, North and South America, Africa, Japan and Oceania, as well as after-sales support for the SSJ 100 family aircraft worldwide. The main goal of opening a joint venture is to achieve a synergy effect and effectively promote the program in developed markets. It is designed to provide aircraft customization for Western customers, as well as after-sales support and a range of services around the world.

On September 26, 2007, the first prototype Sukhoi Superjet 100 with tail number 95001 was rolled out in Komsomolsk-on-Amur, and on February 20, 2008, in preparation for the first flight, the SaM146 engine race was held. On May 14, the aircraft was first tested on the runway: taxiing and jog of the aircraft were practiced, runs were performed with a gradual increase in speed up to 162 km / h, almost to the speed of separation of the front landing gear, and on May 19, 2008, the first flight of the SSJ 100 took place board number 95001. By October of the same year, the SSJ 100 passed the factory test cycle and began the certification process at the Interstate Aviation Committee. The Sukhoi Design Bureau type certificate for the Sukhoi SuperJet 100 aircraft was issued on February 3, 2011.

On February 3, 2012, the SSJ-100 aircraft received a type certificate from the European Aviation Safety Agency (EASA). To obtain the EASA certificate, various tests of the liner were carried out, among which was an imitation of the blow of a fragment of a pneumatic into the fuel tank cap and confirmation of the fire resistance of a flap made of composite materials. Such tests are carried out after the Aérospatiale-BAC Concorde 101 supersonic passenger airliner crashed near Paris on July 25, 2000 due to a damaged fuel tank. operate SSJ 100 aircraft. Thus, the Sukhoi Superjet 100 became the first Russian passenger airliner certified in accordance with the CS-25 EASA aviation rules.

The first airlines to start commercial operation of the SSJ 100 on regular flights in 2011 were Aeroflot and Armavia.

Technological solutions

The aircraft was built according to the normal layout scheme - a twin-engine turbofan low-wing aircraft with a swept wing and a single-keel plumage. Single-slotted flaps are used in the design of the supercritical wing. Part of the mechanization of the wing, as well as the nose fairing and fairing of the root part of the wing are made of composite materials.

The maximum cruising speed of the Sukhoi Superjet 100 is Mach 0.81, the cruising altitude is 12,200 m. extended range - 4578 km.

The uniqueness of the Sukhoi Superjet 100 aircraft family lies in the fact that the latest technologies are used not only in the aircraft itself, but also at all stages of its creation - from design to assembly, which, in turn, guarantees the creation of a modern aircraft that meets the requirements of the world market.

When designing the cockpit, such promising solutions of modern aircraft industry as a “passive” side handle and “active” engine control levers were taken into account. The use of the Human Centered Design concept made it possible to optimize the placement of control levers and instrumentation in such a way that it is possible to complete the flight by one pilot even in the event of an emergency. These solutions, combined with the concept of "Dark and Quiet Cockpit", ensured the possibility of precise, comfortable and reliable piloting of Sukhoi Superjet 100 aircraft.

An additional gain in fuel efficiency, as well as high flight safety, is achieved due to the optimal piloting of aircraft in automatic mode and the protection of the flight control system from random errors. The remote control system is based on three dual-channel computers of the upper level (PFCU - Primary Flight Computer Unit), supplementing the dual-channel computers of the lower level (ACE - Actuator Control Electronics). PFCUs process command signals from the cockpit, autopilot and avionics and optimize the aircraft's flight performance in all flight modes. The level of functional saturation implemented in the PFCU was developed taking into account the experience of the Sukhoi Design Bureau in creating a remote control system with automatic limitation of the limiting and operational flight parameters under manual and automatic control. Thus, the highest level of safety is ensured at all stages of the flight, not only due to the high reliability of aircraft systems, but also due to the unique functionality of protection against errors associated with the "human factor". The SSJ 100 is the first regional aircraft with a CDS of this level. In the event of a series of serious failures on board, the CDS will switch to a backup control loop that provides flight performance at the level of a non-automated (conventional) aircraft.

The use of a fully fly-by-wire flight control system, retracting / retracting the landing gear and braking system speaks of the high operational manufacturability and weight perfection of the Sukhoi Superjet 100.

The fail-safe architecture of the remote control system made it possible to completely abandon mechanical redundancy. The horizontal stabilizer is also controlled electrically. This helped to optimize its dimensions to reduce the level of aerodynamic drag and balancing losses. For the first time on the Sukhoi Superjet 100, algorithmic protection against touching the runway with the tail was applied in case of a pilot's error during takeoff, which made it possible to abandon the use of massive mechanical shock absorbers that other aircraft are equipped with.

The open architecture of the avionics complex was designed by THALES based on integrated modular technology. This made it possible to reduce the number of structural blocks of the complex by about 15% and, thereby, simplify its maintenance. For this, an on-board maintenance system is provided that is capable of detecting failure - down to the structural unit in all major aircraft systems. Along with this, the basic avionics configuration is more functional than its closest competitors. It includes a triple VHF communication system with ACARS function, second generation T2CAS collision avoidance system, ICAO category IIIA approach capability.

SaM146 engines

The development and production of the SaM146 engine for the entire family of aircraft is carried out by PowerJet, a joint venture between the French company Snecma, which today is one of the world's largest engine manufacturers, and the Russian NPO Saturn. Thanks to the new technologies embedded in the SaM146 engine, all aircraft of the family exceed the current and future ICAO requirements in terms of noise and emissions.

Passenger comfort

The SSJ 100 offers unparalleled passenger comfort, with a fuselage section that has increased the aisle to 510mm and offers best-in-class aisle height with five comfortable seats abreast. The height in the aisle to the ceiling is 2,120 mm. Seat width - 465 mm.

With a configuration of four seats in a row, a full-fledged business class is obtained with the same level of comfort for all passengers.

Passengers have easy and convenient access to the shelves, which can easily fit hand luggage with dimensions approved by IATA standards - in 2015 55x35x20 cm. time of year and region.

Modifications

In October 2015 at TsAGI im. Zhukovsky began life tests of the airframe of the regional aircraft SSJ-100-95LR. This is a long range model. Life tests should confirm the design life of the SSJ-100-95LR model up to 70,000 flight hours and 54,000 flights. At present, the design service life of the SSJ-100-95LR model, which has been supplied to airlines since 2013, has been confirmed at 9,000 flight hours and 6,000 cycles.

The SSJ 100-95LR modification differs from the base model in an increased flight range (4,578 km versus 3,048 km), an increased takeoff weight of up to 49.45 tons, and a reinforced wing for an increased takeoff weight. The aircraft is equipped with a SaM146-1S18 engine with a 5% increase in takeoff thrust compared to the modification of the SaM146-1S17 engine.

In 2018, the Sukhoi Civil Aircraft Company plans to create a new modification of the Superjet - a machine with an extended fuselage SSJ-100SV (Stretched Version). Previously, this project was called SSJ 100NG (New Generation). It is assumed that the extended version of the SSJ 100SV will accommodate from 110 to 125 passengers. The new model will have a takeoff weight of slightly more than 55 tons. In total, it is planned to sell 140 SSJ 100SV aircraft by 2031 inclusive. It is planned to bring the SSJ 100SV to the market in 2020. TsAGI is already blowing the SSJ 100SV model in a wind tunnel.

As of January 1, 2016, 101 Sukhoi Superjet 100 (SSJ-100) were built, 76 of them were handed over to customers.

On January 29, 2016, it became known that the European Aviation Safety Agency (EASA) approved the extension of the type certificate of the Aviation Register of the Interstate Aviation Committee (AR IAC), confirming the ability of the Sukhoi Superjet 100 (SSJ-100) aircraft to land in automatic mode in accordance with CAT standards IIIa ICAO.

Specifications

| Model | SuperJet100-95B | SuperJet100-95LR |

|---|---|---|

| Length | 29.94 m | |

| Height | 10.28 m | |

| Wingspan | 27.80 m | |

| Fuselage diameter | 3.24 m | |

| Maximum takeoff weight | 45880 kg | 49450 kg |

| Maximum landing weight | 41000 kg | 12245 kg |

| Empty weight | 24250 kg | |

| Bearing surface area | 77 m2 | |

| Cruising speed | 830 km/h / 0.78M | |

| Max speed | 860 km/h / 0.81M | |

| flight altitude | 12200 m / FL400 | |

| Engines | 2 × SaM146-1S17 | 2 × SaM146-1S18 |

| Maximum thrust in takeoff mode |

2×76.84 kN | 2×79.00 kN |

| Range of flight | 3048 km | 4578 km |

| Crew | 2+2 | |

| Passenger capacity | 98 in basic configuration (up to 108) | |

| passenger doors | 4 | |

| The volume of luggage compartments | 21.7 m 3 | |

| Takeoff run | 1731 m | 2052 m |

| Run length | 1630 m | |

| Fuel supply | 15805 l | |

| Auxiliary power unit | Honeywell RE220 | |

| The first flight | May 19, 2008 | February 12, 2013 |

Options for the basic layout of the SSJ 100/95 aircraft cabin

|

Two class layout 86 chairs, pitch: 8C/90 cm + 78Y/80 cm Standard size galley in forward bay, 2 toilets |

|

Standard single-class layout 98 chairs, step 80 cm |

|

Single class layout 103 chairs, pitch 77.5 cm Small on-board kitchen in the forward compartment, 2 toilets |

Photo of the board of the Mexican AK Interjet and the cockpit - Marina Lystseva (http://fotografersha.livejournal.com/677345.html)

Sukhoi Superjet 100 (SSJ100) is a Russian regional 100-seat passenger aircraft developed by Sukhoi Civil Aircraft with the participation of a number of foreign companies.

The first flight of the SSJ100 took place in May 2008, and now the 100th aircraft is in production. Today, the aircraft is operated by Russian airlines - Aeroflot, Gazprom Avia, Yakutia, Center-South, Red Wings, the Mexican airline Interjet and special departments of government agencies.

1.

SSJ100 is the first Russian aircraft fully designed on the basis of digital technologies.

In its production, technologies not previously used in domestic civil aircraft construction are used, such as stackless assembly, automatic docking of airframe units, automatic riveting, and others.

2. The production of the aircraft, its final assembly, is carried out by the Komsomolsk-on-Amur (Khabarovsk Territory) branch of CJSC Sukhoi Civil Aircraft (KnAF) with the direct participation of other plants in Russia, where components of the Sukhoi Superjet 100 are manufactured.

3. Branch of OJSC “Company “Sukhoi” “NAZ im. V.P. Chkalov" in Novosibirsk produces parts and aggregate assembly of fuselage and empennage compartments.

4. Cabin frame assembly.

5. Details and sections are transferred to the Komsomolsk-on-Amur branch of CJSC Sukhoi Civil Aircraft, where the final assembly of the aircraft is carried out.

6. Fuselage assembly shop (CSF). Here, the finished compartments are docked at the automatic docking stand and fasteners are installed at the joints of the compartments.

7. The fuselage assembly shop consists of four production sections.

8. Compartment docking.

9. More than 600,000 rivets, nuts, bolts, pins and other small parts are used in the production of the SSJ100 aircraft.

10. Here the installation of the floor frame, the installation of passenger, service doors and luggage compartment doors is carried out.

11. At the same stage, the passenger compartment windows and fuselage antennas are installed.

12. Passenger compartment thermal insulation layers are being installed.

13. All works have at least three-level control and verification.

14. After the fuselage assembly shop, the aircraft is moved to the final assembly shop (DSP).

There are 7 production sites here. Today, the production capacity of the plant allows to produce up to 50 cars per year.

15. In this workshop, the empennage of the aircraft is installed, the wings are joined to the fuselage, the landing gear is mounted, the engines are installed, the operability of the aircraft systems is checked, and numerous other operations.

16. Wing mechanization, rudders and elevators, and other parts are made of composite materials. The aluminum parts of the fuselage are coated with a yellow-green primer, and the parts made of composite materials are white.

17. As part of the project, a comprehensive program of technical re-equipment of plants in Komsomolsk-on-Amur and Novosibirsk was carried out.

18. The average age of the company's employees is 35 years.

19. The DSP checks the functioning of the landing gear, prepares the aircraft for energization.

20. The final seventh production site. Here, the final installation of the interior of the baggage and cargo compartment, the interior of the cockpit is carried out, the general technical inspection of the aircraft is carried out and its transfer to the flight test station is prepared.

21. Testing systems under current.

22. The aircraft is being handed over for flight technical tests. As a rule, the flight program of each new aircraft consists of eight flights during which systems are tested in the air.

23. From Komsomolsk, the SSJ100 flies to Ulyanovsk for interior installation and painting in the colors of the customer airline, and then to Zhukovsky to the Delivery Center.

24. Aviation technical base and flight test complex (LIC) of "Sukhoi Civil Aircraft" (SCAC).

25. The GSS hangar in Zhukovsky accommodates 8 aircraft at the same time.

28.

29. The Sukhoi Superjet 100 is powered by two SaM146 turbofan engines manufactured by PowerJet, a joint venture between Snecma and NPO Saturn. The SaM146 was specially designed for the Sukhoi Superjet 100 aircraft.

The SaM146-1S17 thrust class (Basic version) is 17,300 lbs, the SaM146-1S18 (Long Range version) is 17,800 lbs.

30.

Particular attention is paid to the maintainability of the engine, for example, it is possible to replace the blades without removing the engine from the wing.

31.

Although the aircraft is considered short haul, the Long Range version (SSJ100 LR) is capable of flying over 4,000 km.

32.

The SSJ100's maximum cruising speed of Mach 0.81 (860 km/h) allows it to fly at the same levels as the most common types of short haul aircraft: Boeing 737 and Airbus 320, thereby optimizing not only fuel costs, but also time flight costs.

33.

SuperJet International (SJI) is engaged in the training of flight and engineering personnel of customers for the SSJ100 aircraft.

Two training centers were established: in Zhukovsky (Moscow region, Russia) and in Venice (Italy).

Aviation personnel training centers provide a full cycle of training for flight and engineering personnel of SSJ100 aircraft customers. They are equipped with the latest teaching aids and exercise equipment.

To date, SJI has successfully trained nearly 500 pilots, over 200 flight attendants and over 1,700 maintenance technicians.

34. The cockpit. The avionics are made by the French firm Thales, which also makes them for Airbus.

35. The use of the Human Centered Design concept made it possible to optimize the placement of control levers and instrumentation in such a way that it is possible to complete the flight by one pilot even in the event of an emergency.

36. All inscriptions are completely in English.

37. Management is carried out by a side handle, steering columns were abandoned at an early stage of design as an outdated and unpromising technology. As a result, the SSJ100 became the first Russian serial civilian aircraft with a sidestick.

38. The maximum passenger capacity of the aircraft is 103 seats.

39. The cabin height in the aisle is 2.12 m, which allows tall passengers to be in the cabin at full height.

40. The layout of the passenger seats "3 + 2". There is no "B" seat on board the Superjet

The usual designation of seats for flight attendants working on aircraft types A320 and B737, where the passenger cabin configuration was ABC + DEF, was: A - a seat near the window, B - a seat in the middle, C - a seat near the aisle. Thus, it was decided that place B should be excluded, leaving the usual name and location: A - a place near the window, C - a place near the aisle, and on the other hand, everything is unchanged - DEF.

41. Increased living space for each passenger: the large seat pitch in the SSJ100's basic configuration (81.28 cm) allows even tall passengers to feel comfortable in the seat.

43. "Past and present". SSJ100 Against the backdrop of the legendary Tu-144

44. Today, the Sukhoi Superjet 100 route network includes more than 130 cities around the world. Sukhoi Superjet 100 has confirmed its successful operation in a wide range of climatic conditions - at temperatures from -54°С to +45°С: in the Central and Southern parts of Russia, in the Far North, in Indonesia, Laos and Mexico.

45. In May this year, the total number of commercial flight hours of Sukhoi Superjet 100 aircraft in airlines amounted to more than 100,000 since the start of operation in April 2011.

46. It is expected that an Addendum to the Type Certificate will be received in the near future, expanding the operating conditions of the SSJ100 to +50 degrees. All tests have already been carried out and now the paperwork is underway. In addition, taking into account the needs of potential customers, the company plans to expand the conditions for the height of home airfields - 3300 meters above sea level.

47. Some changes will be made to the design of the airframe. For example, the SSJ100 will receive new wingtips designed to optimize aircraft performance and reduce overall fuel consumption by 3% to 4%.

I thank the press service of Sukhoi Civil Aircraft CJSC, as well as the company's employees from LIK / ATK Zhukovsky and KnAF for their help in organizing photography!

For all questions regarding the use of photographs, write to e-mail.

The new short-haul aircraft of the Sukhoi Superjet 100 model was manufactured in the Russian Federation by the Sukhoi company with the support of foreign companies. This machine is designed specifically for the transport of passengers. For this, two modifications were created, which differ in the number of seats for passengers. One device is capable of carrying 75 passengers, and the second - 95. In addition, there are models that are designed for longer flights.

The design of the aircraft for short and medium flight distances was started in 2000, during the development it was called a regional aircraft for Russia.

A brief chronology of the creation of the Sukhoi Superjet 100 aircraft

In the spring of 2003, at the aircraft design competition, the project under the working name RRJ (No. 97 002) won. In 2006, we started assembling a prototype of this device. The machine was assembled at KnAAPO, and a year later this project was delivered to the city of Zhukovsky for further testing at the TsAGI bureau. The product was transported to this city using the Ruslan aircraft.

The first prototype of the Sukhoi Superjet 100 aircraft was presented in September 2007. For the first time, this aircraft model took off from the runway a year after the presentation, namely in May 2008. But before the first flight, the designers spent a lot of time checking all the main systems of the machine.

By the end of 2008, the Sukhoi Superjet 100 aircraft completed factory tests, and the process of state certification began with the participation of an international commission. Resource studies of the aircraft took place at the Siberian Research Institute. The second machine was completely ready by December 2008, during testing this machine showed excellent flight characteristics.

This device was presented to the general public at the air show in the city of Le Bourget in the summer of 2009. The aircraft model Sukhoi Superjet 100, fully equipped with all systems and with a fully equipped passenger compartment, made its first flight only in the summer of 2009.

Aircraft features

The creation of this machine took place in close partnership with foreign aviation companies. The world-famous Boeing Corporation acted as the main consultant for the creation of the Superjet. In the manufacture of this machine, more than 30 companies were involved, which supplied components for the aircraft.

The aircraft is equipped with a high-quality remote control system provided by Liebherr Aerospase. The onboard equipment of the machine was provided by the Thales Corporation. Even all components of the passenger compartment were designed and provided by Aerospase. In addition to all this, such systems as the chassis, hydraulic system, fuel system, brakes, power supply were also provided by foreign companies. All this made it possible to equip the new aircraft with the most modern digital control systems, which helped to achieve high results.

The aircraft has a classic low-wing design scheme, which is equipped with two new generation turbojet engines. The plumage of the machine has a swept shape with a single-keel design scheme. The power plant is represented by two SaM146 engines, which are attached to the wing pylons of the aircraft. The remote control system that this aircraft is equipped with can automatically control the vessel. In addition, there is the possibility of remote release of the chassis and control of the brake system. The control system is so high-quality and safe that it made it possible to completely remove the mechanical control of the apparatus. With this system, you can control the stabilizers.

For the first time, an aircraft designed by the Sukhoi design bureau is equipped with a system that protects the aircraft from touching the runway with its tail during landing or takeoff, even in the event of a pilot error. The on-board system performs a complete analysis of all aircraft systems and notifies pilots of even the slightest malfunctions.

As for avionics, there are also innovations and innovations. It is equipped with a triple high-quality UVC communication system. It protects the car from collisions in the air with other aircraft. The Sukhoi Superjet 100 aircraft is equipped with a system that allows landing with minimal pilot participation and belongs to ICAO category IIIA. As for the uniqueness between other aircraft of the Sukhoi Design Bureau, it should be noted that the aircraft of the Sukhoi Superjet 100 model is 95% unique and has almost nothing in common with previous OKB models.

At the beginning of 2015, 88 Sukhoi Superjet type aircraft were manufactured. Among them were 8 prototypes, and 56 of them were handed over to customers.

As for commercial operation, it began in 2011 with the first flight from Yerevan to Moscow. This flight was carried out by an Armenian company that purchased this airliner. It is also used by Aeroflot, which purchased 10 aircraft. But these machines are supplied at a discount, since Aeroflot allegedly shares the risk of operation with manufacturers. In addition, this Sukhoi Design Bureau machine is used in Yakutia, Indonesia, Vietnam, Mexico and other regions of the globe.

In addition to numerous advantages, the Sukhoi Superjet 100 also has disadvantages. The standard machine is designed for a takeoff weight of 49.5 tons. But most sales are focused on the model, which has 95 seats, and at the same time it has a mass of 45.9 tons at takeoff. This model had to be improved and the structure of the machine had to be strengthened, which led to an increase in weight, and as a result, to high fuel consumption during flight.

Despite everything, this aircraft is truly a breakthrough in the domestic aircraft industry and will be able to bring our aviation industry to world markets.

The Sukhoi Superjet 100-95 (abbreviated certification name for the RRJ aircraft family - SSJ 100, ICAO designation: SU95) is a short-haul Russian passenger aircraft developed by Sukhoi Civil Aircraft Company together with a number of foreign companies.

05/28/2014 At the moment, 5 pre-production, 38 production aircraft and one airframe for static tests and one more for life tests have been built.

Exploitation

04/19/2011 Armavia, an Armenian airline experiencing financial difficulties, purchased the first production Sukhoi Superjet 100 (tail number EK-95015), and two days later performed its first flight from Yerevan to Moscow. This date was the beginning of the commercial use of aircraft of this type. The flight arrived at Terminal C of Sheremetyevo Airport at 4:45 Moscow time. More than 90 passengers were on board the aircraft.

In August 2012, Armavia announced the abandonment of the previously acquired Superjet aircraft.

Sukhoi Superjet 100 and MS-21 - Russian civil aviation

Aeroflot

The first commercial flight of an aircraft with tail number RA-89001 under the flag of Aeroflot took place on June 16, 2011 on the route Terminal D, Sheremetyevo, Moscow (09:10 Moscow time) - Pulkovo, St. Petersburg (10:40 Moscow time) .

Interior layout SSJ 100

Specifications ssj-100:

Length: 29.94 m.

Height: 10.28 m.

Wingspan: 27.80 m.